Are you also troubled by static electricity ? Let's talk the Antistatic mesh belts together.

Application of Antistatic mesh belt in the Wood-based panel industry - Particle board, MDF, HDF, OSB, Plywood production line.

When machines are running at high speed, friction will generate static electricity, which is very harmful and will cause wood chips to float. It not only affects the quality of the output wood boards, but also causes safety problems in serious cases.

Standard machine conveyor belt choice is polyester mesh, Polyester belts is made of PET material, and its strength is several times that of canvas, nylon and general plastic mesh. In addition, Polyester belts has the advantages as follow:

① High temperature resistance - Up to 200 degrees

② Good air permeability - Generally 300-500 cfm, if need can reach more than 1000 cfm.

③ High heat transfer efficiency, which saves energy for users.

Antistatic mesh belts can release static electricity by wearing conductive fiber monofilaments in the polyester mesh, thereby playing an antistatic role. The electric conductivity can reach 5 x 10m³. According to the different materials of the conductive wire, it can be divided into two types:

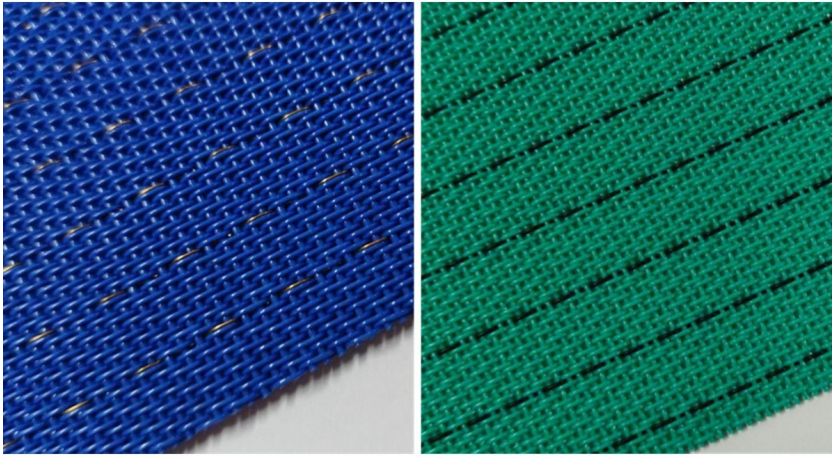

1. Copper wire antistatic mesh:

2. Carbon wire antistatic mesh belt:

Choose the belt that suits you according to your specific use location.

Hope the above information is helpful to you.

Our main belts have Pre-press Belt, Ventilation Belt, Spreader Belt, Press Infeed Belt, Bin Bottom Belt, Sanding Belt and etc in the production process of MDF, HDF, PB, OSB, SPB, LVL, and other wood boards.

If you have any needs, please call us for inquiries. We are happy to share HUATAO's successful experience.

Email: bella@huataogroup.com

Whatsapp: +8617731169773

Website: www.huataobelt.com

can not be empty

can not be empty