Raw materials: Polyester

Joint: Z-Splice

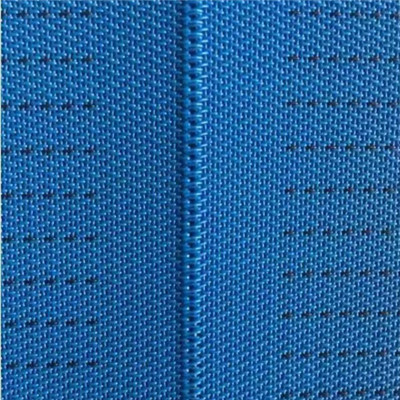

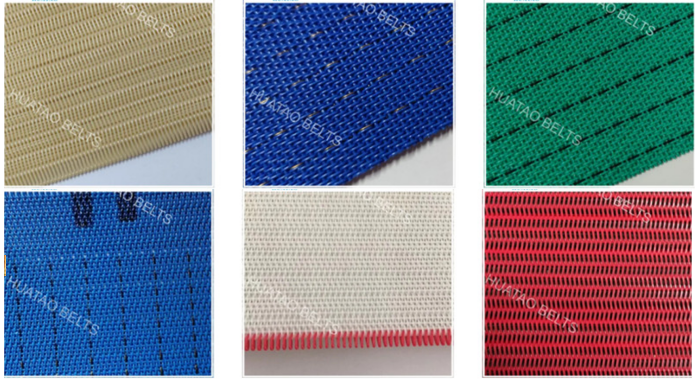

Color: Blue

Antistatic: Yes

Weft plus conductive thread (Material): Corbon Filament

Thickness: 1.95mm

Air Permeability: 200-500CFM

Deaeration Belt

Deaeration Belt are for Pre-compressing the chip, which is popular in the MDF and Particle Board Manufacturing for their smoth surface and high level air permability.

Deaeration Belt uses a special silk thread, which is wear-resistant and tensile-resistant and can adapt to any chemical substances introduced in the wood-based panel industry, making the mesh belt have excellent breathability. The antistatic black silk thread makes the mesh belt have good antistatic and anti-sticking properties, effectively preventing fibers from blocking the mesh belt and improving production efficiency. The joints use endless, pin rings, and spiral rings, which can be selected according to the specific use of customers.

Deaeration Belt have a high proportion of warp threads, are highly air permeable and have a very smooth surface. The extremely strong Z-splice.

Deaeration Belt Advantages:

1. Fast drying speed: The ventilation belt can quickly absorb the moisture on the wood surface, thereby speeding up the drying speed.

2.Uniform drying: The ventilation belt can evenly dry the wood surface, avoiding the problem of uneven local drying.

Environmental protection: The ventilation belt drying method does not require the use of chemical agents and is environmentally friendly.

Low cost: The cost of the ventilation belt drying method is relatively low and suitable for large-scale production.

Deaeration Belt Feature:

1.Excellent tracking properties

2.Balanced air permeability

3.Easy cleaning

4.Excellent anti-static properties

5.Good abrasion and chemical resistance

Deaeration Belt Specifications:

|

Belt type |

Filament diameter |

Density/root |

Tensile strength |

Warp and weft plus conductive thread (Material) |

Thickness |

Air permeadility |

Air permeadility |

Electric conductivity |

|||

|

|

Wrap |

Weft |

Wrap |

Weft |

surface |

jont |

|

|

|

|

|

|

31505 |

0.4 |

0.5 |

33 |

9 |

1600 |

900 |

Copper wire |

1.3 |

2976 |

186 |

5X103 |

|

14804K |

0.68 |

0.8 |

14.8 |

7.2 |

2000 |

900 |

Copper wire |

1.95 |

6800 |

430 |

5X103 |

|

14804T |

0.68 |

0.8 |

14.8 |

7.2 |

2000 |

900 |

Carbon filament |

1.95 |

6800 |

430 |

5X103 |

|

4106-3 |

0.5 |

0.30/0.70 |

22.8 |

12.6 |

2200 |

900 |

Copper wire |

1.8 |

8000 |

500 |

5X103 |

|

14708 |

0.64 |

0.7 |

15 |

8 |

2000 |

900 |

Carbon filament |

1.78 |

11200 |

700 |

6X103 |

|

12708 |

Flat wire |

0.7 |

14.1 |

7.3 |

2000 |

900 |

Carbon filament |

1.76 |

8000 |

500 |

6X103 |

Deaeration Belt Photos for reference:

Company Introduction:

HUATAO's Belts for wood-based panels has good flexibility, easy deviation correction, firmness and durability.

HUATAO has been focusing on the belts production of wood-based panels for more than 20 years. Through continuous research and development and experiments in recent years, it has been proved that our products are targeted and applicable to all wood fibers, particle boards, medium fibers, oriented strand boards, cardboards and softboards. At present, they have been widely used in equipment such as Simbelcomb, Dieffenbacher, Shanghai Board Machine, Dunhua Yalian, etc. At domestic and abroad market, and are well received by customers.

Based on many years of experience in the wood industry, through understanding the actual working conditions, continuous optimization of the conveyor belt raw material formula and adjustment of the production process, Huatao wood conveyor belts are stable and perform well in the board laying and forming, pre-pressing, sanding, spraying and other sections, providing stable support for wood processing day after day.

Huatao's wood conveyor belts cover a variety of applications including artificial board production, slab sanding, board edge banding and paint spraying. Our experienced sales engineers can provide customers with a full range of product options and can customize personalized selection plans according to your diverse needs.

Our main belts have Pre-press Belt, Ventilation Belt, Spreader Belt, Press Infeed Belt, Bin Bottom Belt, Sanding Belt and etc in the production process of MDF, HDF, PB, OSB, SPB, LVL, and other wood boards.

If you have any needs, please call us for inquiries. We are happy to share HUATAO's successful experience.

can not be empty

The E-mail format is not correct

can not be empty